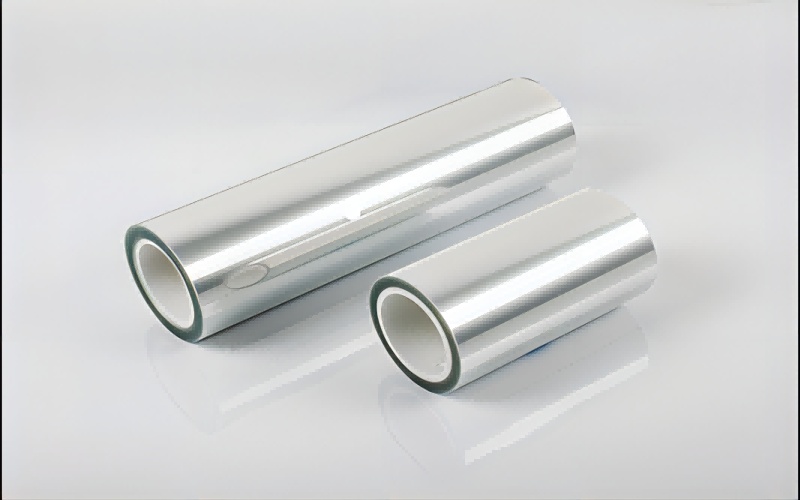

Non-silicon release film

No silicon, no silicon transfer pollution problem.

Stable release force, high residual rate.

Can fit silica gel, silicone gel, the price is cheaper than fluorine.

Used in high temperature tape, silicone protective film, label, cellophane, etc.

Non-silicon release film

Non-adhesive surface: One of the primary benefits of non-silicon release films is their non-adhesive surface, which allows them to be easily removed from any surface without leaving behind any residue. This feature makes them ideal for use in applications where residue-free removal is crucial, such as in the electronics industry.

High temperature resistance: Non-silicon release films can withstand high temperatures, making them suitable for use in hot environments or during high-temperature processes. This feature ensures that they remain stable and functional even under extreme conditions.

Chemical resistance: Non-silicon release films exhibit excellent chemical resistance, making them suitable for use in applications involving harsh chemicals or solvents. This feature ensures that the films remain stable and functional despite exposure to corrosive substances.

Easy to apply and remove: Non-silicon release films are easy to apply and remove, thanks to their non-adhesive surface. This feature simplifies the process of installing and removing them, reducing the risk of damage to the underlying surface or the film itself.

Low-friction properties: Non-silicon release films possess low-friction properties, which minimizes the risk of sliding or slipping during application and removal. This feature ensures that the films remain securely in place and perform well in high-friction environments.

Wide range of applications: Non-silicon release films are versatile and can be used in a wide range of industries, including electronics, automotive, aerospace, and construction. Their unique properties make them ideal for various applications, such as insulation, protective covering, and adhesive backing.

Environmental friendliness: Non-silicon release films are typically made from non-toxic and renewable materials, making them an eco-friendly alternative to traditional silicon-based release films. This feature makes them a sustainable option for applications where environmental concerns are a priority.

Cost-effective: Non-silicon release films offer excellent performance at a competitive price, making them a cost-effective solution for various industrial and commercial applications.